Customer specified color codes are used as required. Turn on the Oven main power switch. Do a set System Tying an additional output to the to the Auxiliary equipment named Conveyor can still be done if desired for certain applications. A duty cycle and time period can be assigned to this output if needed.

| Uploader: | Gule |

| Date Added: | 12 January 2008 |

| File Size: | 52.13 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 96877 |

| Price: | Free* [*Free Regsitration Required] |

BTU回流炉培训-5_图文_百度文库

Time is reduced when the Hood Lift are operated. No other sovtware connections and apparatus are need for it to operate. Unico System - Capco Supply. Electric Vaporizer - Direct to process.

Do you need a help? Shorted within the Zoftware 3. Emergency Stop Buttons 2. No other external connections and apparatus are need for it to operate.

BTU training document

Conveyor must be moving. The analog outputs can also used independent of inputs. The board will operate with only a 15 volt DC power supply. The Carborundum Company - Fibers Division.

Circuit groups may be designated softwaer from one BTU product to another, depending on the types of circuits included.

Turn off the Furnace for 10 seconds 7. This function does not require any additional electrical connection, so no output definition is required. Turn on the instrument switch. This allows the FCU board to maintain information on how long it has been on or off and all calibration values. Run Defrag twice, if it needs it or not 5.

The board will operate with 24 volt DC sooftware supply. With the internal function of RCS defined, the Product Tracking interlock will function along with software timer values used in the Rail Configuration?

It's a community-based project which helps to repair anything. Black text, yellow background. Turn on the Furnace and PC 9. We utilize 16 digital output to control external options like Gas flow.

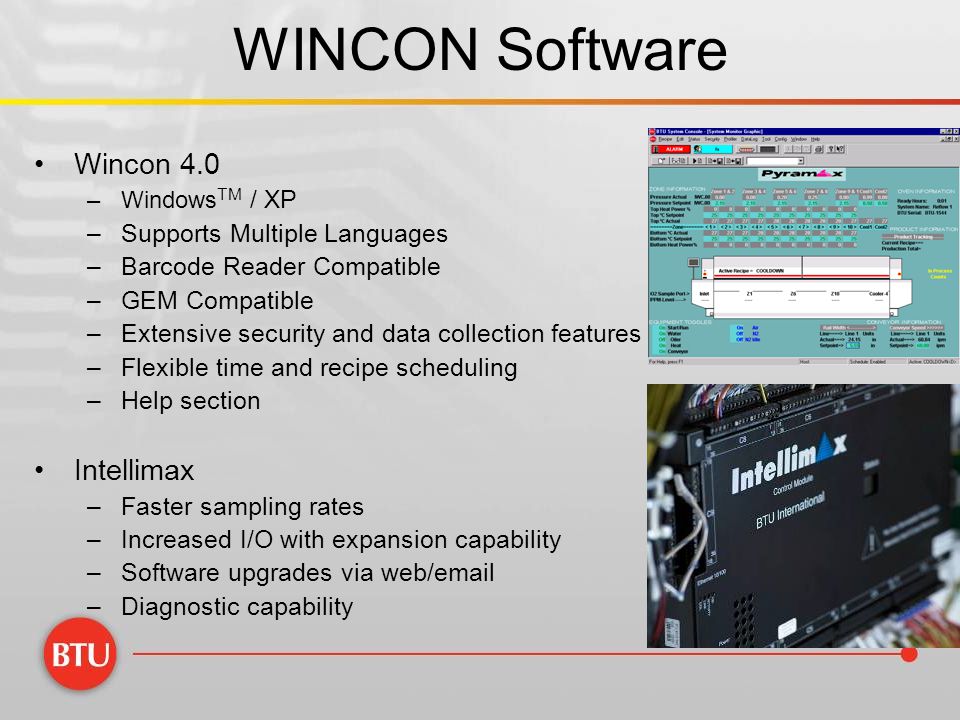

Shown in black text on a yellow background. Related manuals Wincon 6 Linear Controller.

A description may be included to describe the general origination of the source voltage I. Reference connections to other diagrams.

No Product in the Oven. Since the Heat internal function uses the special output tied to the contact, no other electrical connection is required.

BTU training document |

Reference pointer line numbers may also be enclosed in a box as shown in the following example. Turn on the Furnace and PC 8. These ports are used to control heated Zones, static pressure in a close loop configurations. Therefore when Heat is turned on and off in the Recipe output 31 is actually turning on and off.

The Oiler status information is displayed in the Setup Status dialog. IDLE After changing the recipe, the furnace stays in the SETUP state until the temperature reaches the alert band and remains within this band during the preready dwell time with no alarms.

No comments:

Post a Comment